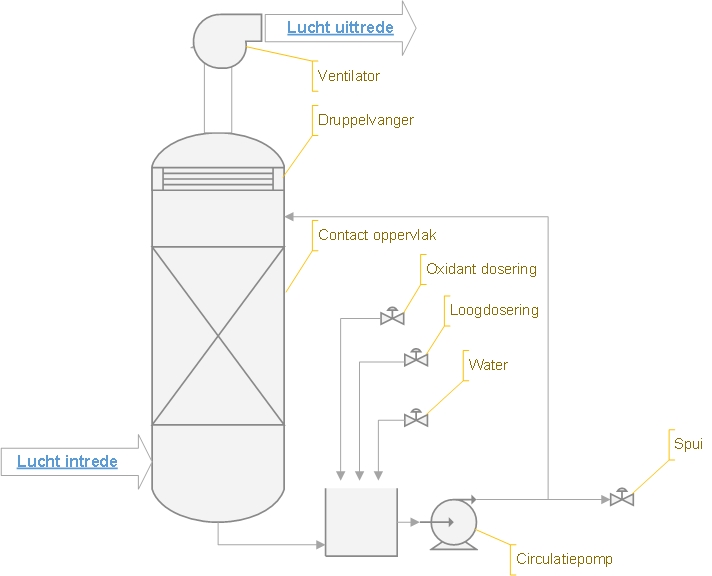

Odour scrubber (Oxidative scrubber) in bakeries and the confectionery industry

Bakery and confectionery products are known for the smell of freshly baked bread and the sweet smell of sugar. Around process lines, however, odour concentrations can also arise that are not as fine or even harmful to employees, the surroundings or the environment. Many substances used in the bakery and confectionery industry dissolve well in water. An air scrubber based on water alone is therefore often sufficient to wash odour components from an air stream. Sometimes the removal of odorous components is more difficult and chemicals need to be added to the washing water. A alkaline oxidative air scrubber is often used for odour control. The organic odour components are oxidized in an alkaline environment, at pH 7 - 12. The most commonly used strong oxidants are sodium hypochlorite (NaOCl), potassium permanganate (KMnO4) or hydrogen peroxide (H2O2).

Odour removal is a very complex matter and depends very much on the composition of the odour components. It is therefore certainly advisable to carry out preliminary tests in order to be able to specifically determine the removal efficiency. Air Solutions can have an odour image charted by continuous monitoring. Depending on the contaminants, it is sometimes desirable to first pass the air through an acidic scrubber, then oxidize odour components in a 2nd stage and finally neutralize everything in an alkaline scrubber.

The advantages of an Air Solutions odour scrubber are:

- Made entirely of plastic to prevent corrosion

- Compact design

- Horizontal and vertical airflow possible

- Very high removal efficiency

- Modularly scaled up, multi-stage systems

- Formed salts can be reprocessed and reused

In addition to odour scrubbers, Air Solutions Holland also offers acid scrubbers, alkaline scrubbers, and plastic chemical storage tanks.

Quality marks:

- ISO 9002

- CE

- KIWA

- VLAREM

- DVS welding certification

DVS

TUV

KIWA

ISO

CE