Alkaline scrubber in bakeries and the confectionery industry

In the bakery and confectionery industry many different fragrances and sweeteners are used. Most fragrances and sweeteners (very often esters) have a very specific strong pungent odour. Because they are already detectable at very low concentrations, air streams with these types of odour components must first be cleaned before they can be exhausted to the outside. Depending on whether an ester behaves acidic or alkaline, an alkaline air scrubber can be a good technical solution to remove ester contaminants from the air.

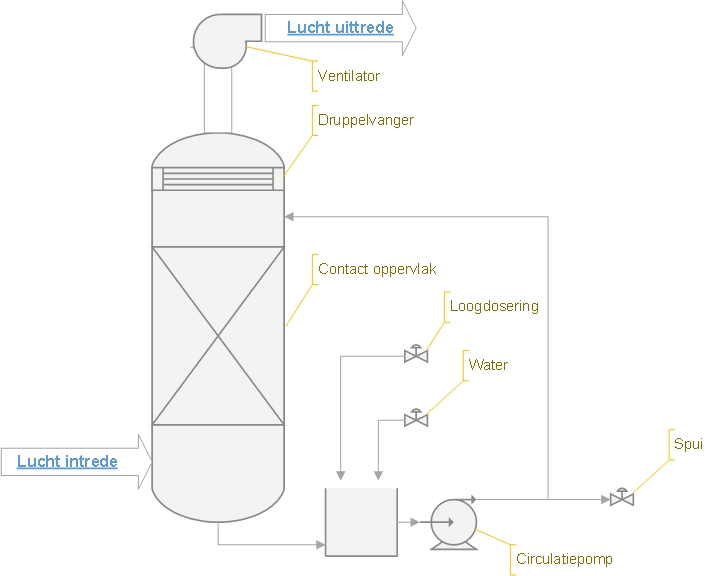

An alkaline gas scrubber will react with acidic components to remove them from the air stream. By adding a base (lye), the pH of the washing water is raised and the acid forming components are neutralized by the lye, whereby salts are formed. The dosing of the base is done by means of a pH control, in most cases the pH value of the washing water varies between 7 and 12.

Depending on the salt formed, more or less washing water is discharged, this is measured on the basis of density and/or conductivity. The drainage can contain up to 15 % of salts and is discharged or evaporated for reuse.

Usually caustic soda (NaOH) is added as a base to the washing water. Often an alkaline scrubber is designed in combination with an odour scrubber. Besides caustic soda, a chlorine solution is dosed to oxidize all odour components. For more information please refer to the odour scrubber.

Alkaline scrubber in bakeries and the confectionery industry

In the bakery and confectionery industry many different fragrances and sweeteners are used. Most fragrances and sweeteners (very often esters) have a very specific strong pungent odour. Because they are already detectable at very low concentrations, air streams with these types of odour components must first be cleaned before they can be exhausted to the outside. Depending on whether an ester behaves acidic or alkaline, an alkaline air scrubber can be a good technical solution to remove ester contaminants from the air.

An alkaline gas scrubber will react with acidic components to remove them from the air stream. By adding a base (lye), the pH of the washing water is raised and the acid forming components are neutralized by the lye, whereby salts are formed. The dosing of the base is done by means of a pH control, in most cases the pH value of the washing water varies between 7 and 12.

Depending on the salt formed, more or less washing water is discharged, this is measured on the basis of density and/or conductivity. The drainage can contain up to 15 % of salts and is discharged or evaporated for reuse.

Usually caustic soda (NaOH) is added as a base to the washing water. Often an alkaline scrubber is designed in combination with an odour scrubber. Besides caustic soda, a chlorine solution is dosed to oxidize all odour components. For more information please refer to the odour scrubber.

The advantages of an Air Solutions alkaline scrubber are:

- Completely made of plastic to prevent corrosion

- Compactly built

- Horizontal and vertical airflow possible

- Very high removal efficiency

- Modularly scaled up, multi-stage systems

- Formed salts can be reprocessed and reused

Air Solutions has experience with basic washers in the following industries:

- MDF wood pressing (formaldehyde)

- Waste treatment plant (hydrogen sulphide H2S)

- Chemical industry (chlorine neutralisation)

- Pharmaceutical industry (phenols and hydrogen fluoride)

In addition to alkaline scrubbers, Air Solutions Holland also offers acid scrubbers, odour scrubbers and plastic chemical storage tanks.

Quality marks:

- ISO 9002

- CE

- KIWA

- VLAREM

- DVS welding certification

DVS

TUV

KIWA

ISO

CE