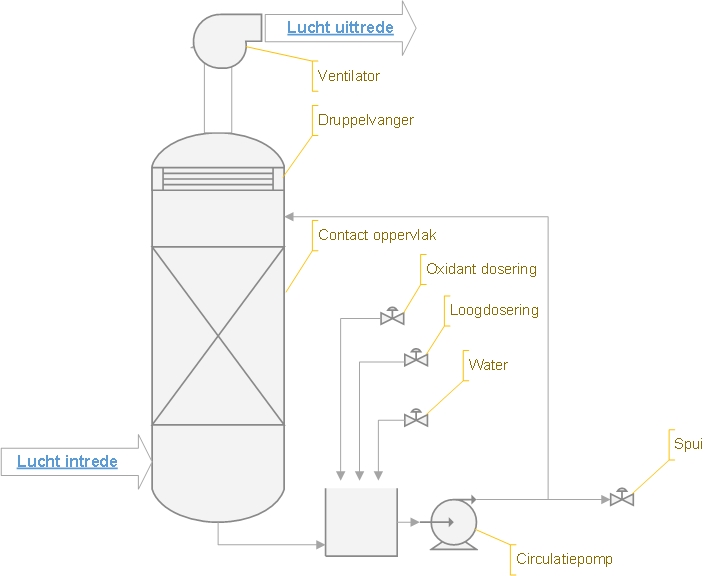

Odour scrubber (Oxidative scrubber) in the energy and biomass industry

Air Solutions Holland has experience with odour scrubbers in the biomass industry. Digestate, the residue of a fermentation installation is sometimes further thickened to be used as a soil improver. However, this type of thickening process often results in air flows that can cause odour and stench pollution. These are often sulphur compounds (hydrogen sulphide but also mercaptans), which are already perceptible in low concentrations. A basic oxidative air scrubber is often used for this type of odour control. The organic odour components are oxidized in an alkaline environment, at pH 7 - 12. The most commonly used strong oxidants are sodium hypochlorite (NaOCl), potassium permanganate (KMnO4) or hydrogen peroxide (H2O2).

Odour removal is a very complex matter and depends very much on the composition of the odour components. It is therefore certainly advisable to carry out preliminary tests in order to be able to specifically determine the removal efficiency. Air Solutions can have an odour analysis carried out by continuous monitoring. Depending on the contaminants, it is sometimes desirable to first pass the air through an acidic scrubber, then oxidize odour components in a 2nd stage and finally neutralize everything in an alkaline scrubber.

The advantages of an Air Solutions odour washer are:

- Made entirely of plastic to prevent corrosion

- Compact design

- Horizontal and vertical airflow possible

- Very high removal efficiency

- Modularly scaled up, multi-stage systems

- The formed salts can be reprocessed and reused

Air Solutions has experience with odour scrubbers in the following industries:

- Slaughterhouses

- Food Industry

- Pharmaceutical Industry

- Waste treatment facilities

Quality marks:

- ISO 9002

- CE

- KIWA

- VLAREM

- DVS welding certification

DVS

TUV

KIWA

ISO

CE