Heat pump in the meat processing and dairy industry

Air Solutions Holland has a number of solutions to optimize the complete energy balance in your plant. In many meat and dairy factories residual heat is available at a low temperature, with the help of a mechanical heat pump this low-grade residual heat can be upgraded to high-grade useful heat, so that the consumption of fossil fuels can be minimized.

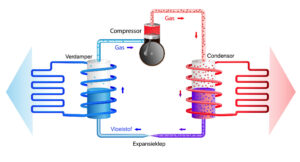

The operation of a mechanical heat pump is based on the compression and expansion of a refrigerant. All refrigerants in a heat pump have a low boiling point, however, the selection of the refrigerant determines the evaporation and condensation pressure and thus the achievable temperature ranges in the system. A heat pump consists of the following main components, an evaporator, compressor, condenser and expansion valve.

In the evaporator, heat is extracted from the available low-grade residual heat flow and transferred to the refrigerant, which, due to its low boiling point, moves from the liquid phase to the gaseous phase. The compressor then increases the pressure and transports the refrigerant to the condenser. In the condenser, due to the higher pressure, the refrigerant will condense again at a higher temperature from the gas phase to the liquid phase and release its heat to the high temperature heat flow. The liquid formed in the condenser is lowered in pressure in the expansion valve and then flows back to the evaporator, where the cycle starts again.

Most of the electrical energy required to drive the compressor is converted into heat which ends up in the refrigerant. This means that more heat can be extracted in the condenser of the heat pump than is absorbed in the evaporator. The efficiency of a heat pump is expressed in the COPh value (coefficient of performance, heating). This is the ratio between the heat that can be beneficially used and the electricity required to drive the heat pump. The COPh value of a heat pump is enormously influenced by the temperature difference between the residual heat and the desired heat flow. With an electric heat pump, temperature differences of 60°C are efficiently achievable. However, the closer the evaporation and condensation temperatures get to each other, the more efficient the heat pump becomes.

In addition to electric heat pumps, gas motor driven systems are also available. In these types of systems, the drive shaft of the compressor is coupled to an internal combustion engine. The combustion engine provides the required drive power by burning natural gas, biogas or oil. As a result, a gas engine heat pump creates extra heat flows from the engine cooling (80 to 90°C) and the flue gas heat exchanger (400 to 500°C) in addition to the condenser heat. The gas engine heat pump therefore releases several heat sources at different temperature levels. Depending on the desired application, the heat flows can be used separately or cleverly combined into one flow of hot water.

The Air Solutions employees are always ready to design and install the best heat pump solution together with you. We also like to look at more than just the heat pump system, like buffer systems, the complete hydraulic housekeeping and control of the complete system.

eurovent

TUV

CE