Rotary heat recovery system in the chemical industry

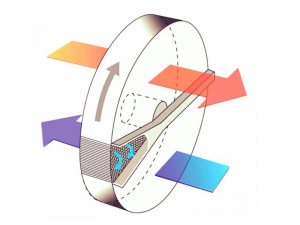

A rotary system exchanges energy by means of a rotating wheel, which is made up of fins that can easily absorb and release heat and cold. The wheel is placed in an air handling unit between the warm exhaust air stream and fresh cold intake air and continuously exchanges energy between these air streams while rotating. Optionally, the rotary system can be fitted with an adsorbent so that, in addition to heat, moisture can also be recovered.

Because everything is built compactly together, there are few losses and the efficiency of a rotary system is often on the high side, between 70-85%. The energy demand can be controlled by adjusting the rotation speed of the wheel. Another possibility is the use of a by-pass duct, in order to recover less energy. The supply air flow is then controlled on temperature, humidity or enthalpy value.

Air Solutions Holland supplies rotary systems in various material choices for the chemical industry, among others:

- Aluminium

- Ceramic

- Plastic (PE, PP, PVDF)