Acid scrubber in the energy and biomass industry

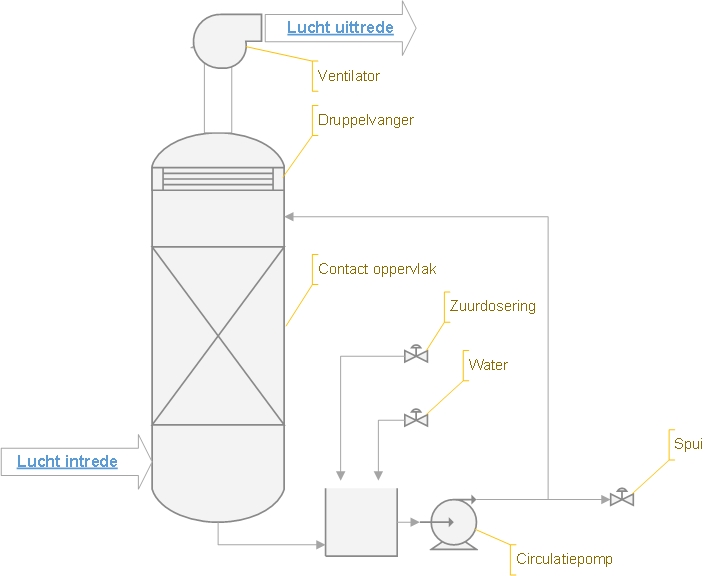

In order to generate energy in a sustainable way, biomass is often fermented (e.g. manure, VGF waste, vegetable oil and wood). During the fermentation process biogas is produced, but especially when manure is fermented, ammonia (NH3) is often released as well. Ammonia is a colourless, poisonous and flammable gas with a characteristic strong pungent odour and can be harmful to humans, animals and the environment in high concentrations. That is why the government imposes strict emission rules on ammonia emissions. An acidic air scrubber is a technically good solution to remove ammonia from air.

In addition to ammonia, an acid air scrubber can remove many more basic components from an air stream. By adding an acid, the pH of the washing water is lowered and the alkaline components react with the acid to form a salt. The dosing of the acid is done by means of a pH control, in most cases the pH value of the washing water varies between 3 and 6.

Depending on the salt formed, more or less washing water is discharged, this is measured on the basis of density and/or conductivity. The drainage can contain up to 15 % of salts and is discharged or evaporated for reuse.

Various acids can be added, sulphuric acid (H2SO4) and nitric acid (HNO3) are usually used. For specific applications, e.g. to capture ammonia (NH3), the acid then forms ammonium sulphate or ammonium nitrate, both salts can be used as fertiliser or soil improver. Because of their alkaline character, amines and esters (odour components) can also be captured in an acid scrubber.

In the case of very large air volumes from which, for example, ammonia has to be removed, several scrubbers should preferably be mounted in parallel. If low end concentrations are desired, it is sometimes necessary to place several scrubbers in series in order to achieve a longer residence time.

In case of strongly acidic air flows with, for example, high concentrations of hydrochloric acid (HCl), the scrubber itself will become acidic. With this type of scrubber, the maximum acidity level must be regulated by means of drainage or by adding a base (alkaline scrubber). Combustion plants often use this type of wet scrubber.

The advantages of the acid scrubber are:

- Completely made of plastic to prevent corrosion

- Compact design

- Horizontal and vertical airflow possible

- Very high removal efficiency

- Modularly scaled up, multi-stage systems

- The formed salts can be reprocessed and reused

Air Solutions has experience with acid scrubbers in the following industries:

- Manure processing (ammonia)

- Composting (ammonia)

- Fermentation (ammonia)

- Waste treatment plant (ammonia, amines)

- Fertilizer production (ammonia)

In addition to acidic scrubbers, Air Solutions Holland also offers alkaline scrubbers, odour scrubbers, and plastic chemical storage tanks.

Quality marks:

- ISO 9002

- CE

- KIWA

- VLAREM

- DVS welding certification

DVS

TUV

KIWA

ISO

CE